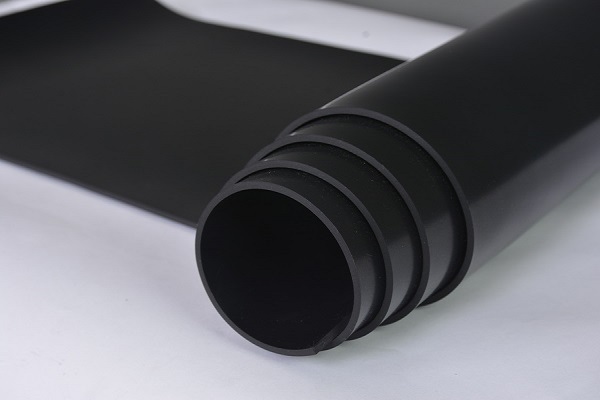

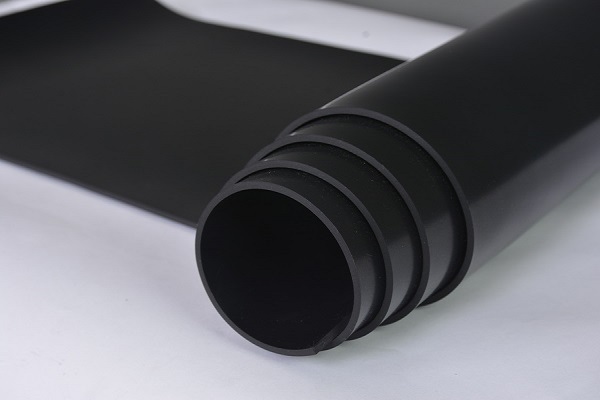

The acid resistance of black rubber mats is a key concern in many industrial fields,as their material properties and application scenarios directly affect their practical performance.These products are mainly made from natural rubber,chloroprene rubber,ethylene propylene diene monomer(EPDM)rubber,and fluorine rubber,processed through special techniques,and can maintain stable performance in various concentrations of acidic and alkaline environments.

From the perspective of material composition,the core advantage of black rubber mats lies in their chemical stability.For instance,chloroprene rubber has excellent oil resistance and anti-aging properties,while EPDM rubber has outstanding resistance to polar solutions,and fluorine rubber can maintain structural integrity under high-temperature and strong corrosive conditions.The combined use of these materials enables the mats to resist weak corrosive media such as dilute acids and dilute alkalis,as well as cope with strong acids and strong alkalis in certain specific environments.Experimental data shows that the working temperature range of some black acid and alkali resistant rubber mats can reach-30°C to 60°C,maintaining elasticity and sealing performance even under extreme temperatures.

>send emails to sales@jingdongrubber.com,get a quote now

In terms of parameter indicators,the specific gravity of common black acid and alkali resistant rubber sheets is between 1.6 and 1.8,the tensile strength reaches 4 MPa,the elongation is approximately 250%,and the hardness is maintained at 75±5 degrees.These physical properties ensure that the material does not deform or crack under long-term pressure and has good resilience.

In practical applications,these mats mainly play three roles.Firstly,they serve as sealing elements for chemical pipelines and storage equipment to prevent damage caused by acid and alkali leakage.Secondly,they are used as protective layers on laboratory workbenches to protect operators from corrosive liquids.Thirdly,they are made into buffer components in precision instruments,utilizing their insulating properties to ensure stable operation of the equipment.

When purchasing such products,three dimensions should be focused on.Firstly,the corresponding material should be selected based on the type of medium,for example,fluorine rubber is more suitable for high-concentration nitric acid environments,while chloroprene rubber has better resistance to hydrochloric acid.Secondly,temperature compatibility should be considered,with priority given to the flexibility of the material in low-temperature environments and testing the coefficient of thermal expansion in high-temperature conditions.Finally,attention should be paid to size matching,including thickness and hardness parameters,which need to precisely match the groove dimensions to avoid seal failure due to improper assembly gaps.

Maintenance and care also affect the service life.It is recommended to regularly check the surface of the mat for cracking or swelling.Minor damage can be repaired by grinding and continue to be used.During storage,avoid direct sunlight,keep away from ozone sources and organic solvents,and the stacking height should not exceed 1.5 meters.

Jingdong Rubber Co., Ltd. is a professional rubber mat manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.