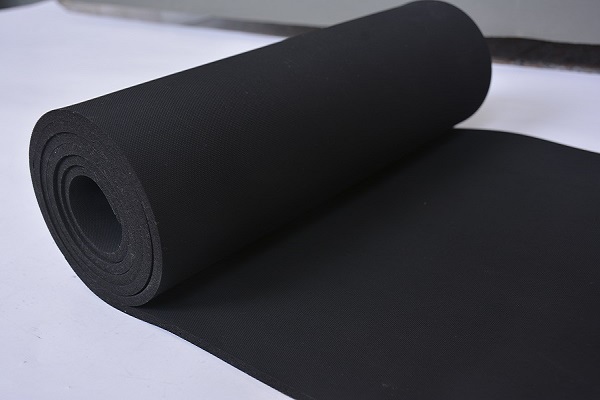

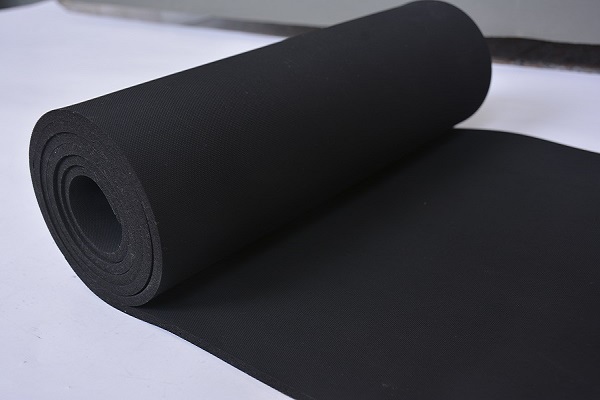

Foam rubber padding is a widely used new material that combines the essence of advanced chemical technology and traditional rubber processing experience.

Essentially,its main components are ethylene propylene diene monomer(EPDM)and styrene butadiene rubber(SBR).During production,manufacturers carefully blend various auxiliary materials,such as specific foaming agents,fillers,vulcanizing agents,and plasticizers.These additives are not randomly selected but are determined through scientific calculations and repeated experiments to optimize the physical properties and performance of the product.

Once these raw materials are fed into the fully automated production line,they embark on a precise transformation journey.

The mixing process evenly disperses and fully integrates all components to form a pliable rubber compound;then it proceeds to the calendering stage,and the crucial foaming phase is achieved through a high-temperature vulcanization process.During this process,the pre-added foaming agents decompose under heat to generate gases,causing numerous small and independent closed-cell structures to form within the rubber.It is precisely this unique closed-cell design that endows foam rubber padding with outstanding thermal insulation and heat preservation properties,while also effectively preventing water vapor penetration,making it an ideal material for building energy conservation.

>send emails to sales@jingdongrubber.com,get a quote now

Foam rubber padding has a wide range of applications.

In the construction industry,it is often used as insulation for pipes or as core material for walls,effectively reducing energy loss due to its low thermal conductivity.In industrial equipment manufacturing,this material provides reliable protection and buffering for machinery due to its good flexibility and shock absorption properties.Even in the interior decoration of transportation vehicles,its excellent sound insulation and noise reduction capabilities are fully utilized.

From a microscopic perspective,the countless closed bubbles inside foam rubber padding act as natural barriers,preventing the formation of heat transfer paths and enhancing the material’s resistance to compression deformation.This physical characteristic ensures that it maintains its shape stability over long-term use and is less prone to aging and cracking due to environmental changes.Additionally,the closed-cell structure also gives the material certain water and moisture resistance,allowing it to maintain normal operation even in humid environments.

Overall,foam rubber padding,as a functional composite material,offers value in multiple dimensions:it not only demonstrates excellent performance based on specific chemical compositions but also provides reliable quality assurance through advanced manufacturing technology.It can meet diverse industry application needs and adapt to changing market trends.

Jingdong Rubber Co., Ltd. is a professional rubber sheet manufacturer, producing silicone rubber sheet, natural rubber sheet, fluorine rubber sheet, neoprene rubber sheet, insulating rubber sheet,EPDM rubber sheets, oil-resistant rubber sheets, anti-static rubber sheets, flame-retardant rubber sheets, conductive rubber sheets, anti-slip rubber sheets, and cowshed mats, etc. with 40 years of industry experience, are popular both at home and abroad. If you need any of our products,please send emails to sales@jingdongrubber.com.